Clean Room Equipment Manufacturer

Let our experts help your cleanroom projects

Safe, Fast and Efficient

GMP Standard

Upgrade your cleanroom

CE Certified

If your project is in Europe, our products comply with CE.

ISO Standard

Make your cleanroom meet international standards

UL Certified

Help your project achieve higher certification.

Shipment Within 15 Days

Save your time and get projects done faster.

High Quality and Better Price

Let your cost be lower and get more profit.

Choosing your cleanroom equipment partner with 20 years of experience

Our experience translates directly into reliable, durable cleanroom solutions that perform consistently in demanding cleanroom environments, minimizing downtime and process interruptions.

Exceptional Journeys with Boben

Our Successful Projects

600+ customers. 72 countries. 6 continents.Reliable Service

Fast, responsive, and focused on your satisfaction.

24/7 Availability

Contact us anytime. We’ve got your back, day or night.

Seasoned Team

Years of hands-on industry experience you can rely on.

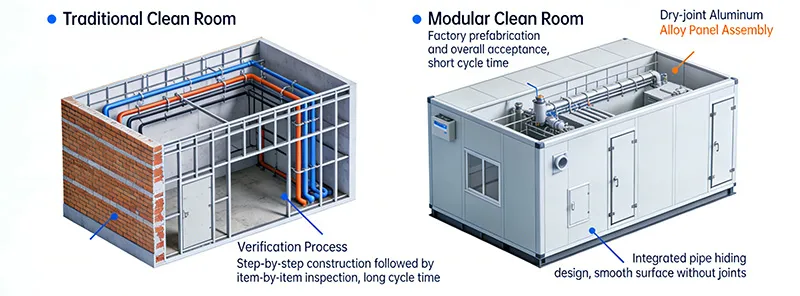

How Much Does a Class 100 Modular Cleanroom Cost in 2026? A Detailed Budget Guide.

With the rapid advancement of the semiconductor, precision optics, and high-end biopharmaceutical industries, enterprises increasingly demand high-cleanliness production environments. Looking ahead to 2026, fluctuations in raw material costs, rising labor…

How to Ensure GMP Compliance for Modular Cleanrooms? 4 Critical Keys

For pharmaceutical and biotechnology companies, GMP (Good Manufacturing Practice) compliance is not an option—it is the baseline for survival. Traditional cleanroom construction, with its 12-18 month timelines and complex validation…

What Are the Benefits of an Air Clean Room? Yield, Safety & GMP Compliance

In high-end sectors such as precision manufacturing, biopharmaceuticals, healthcare, and food processing, cleanrooms are no longer an optional feature but a standard requirement that determines product quality and corporate survival…

What is a Cleanroom in Pharma? Standards, Grades & ISO Compliance

In the pharmaceutical industry, a cleanroom refers to a specialized space that provides a controlled environment for drug production by regulating environmental parameters such as airborne particulate matter, microorganisms, temperature…